The Brief Wondrous Life of Oscar Wao by Junot Díaz explores identity, culture, and family history through Oscar’s journey as a Dominican American outsider. Chapter 1 introduces his struggles with self-acceptance and cultural expectations, setting the stage for themes of belonging and destiny.

Overview of The Brief Wondrous Life of Oscar Wao

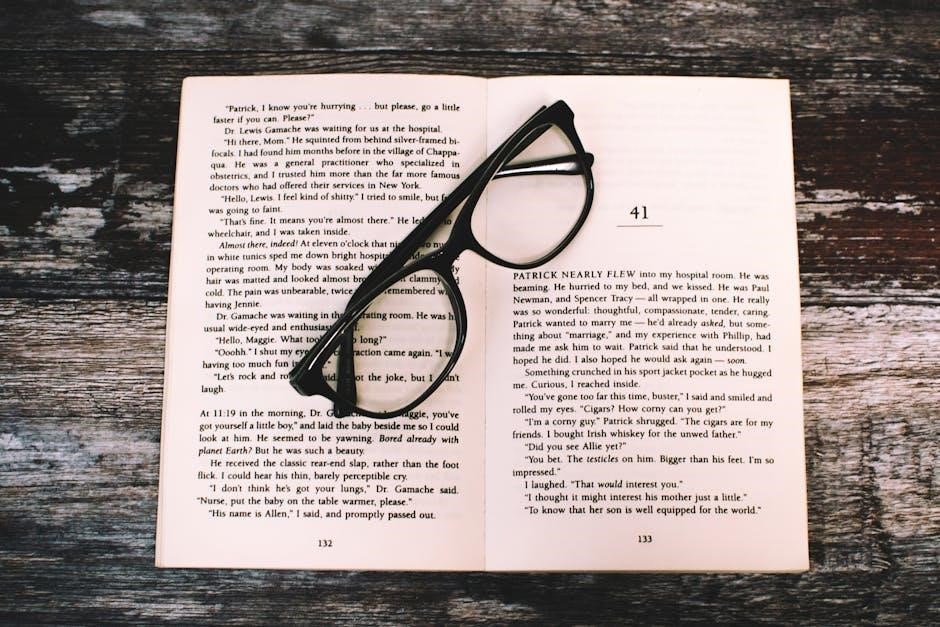

The Brief Wondrous Life of Oscar Wao is a Pulitzer Prize-winning novel by Junot Díaz, blending slang, Spanglish, and magical realism. It follows Oscar, a young Dominican American outsider, as he navigates identity, culture, and family curses. The story, narrated by Yunior, explores themes of belonging, love, and destiny, set against the backdrop of the Dominican diaspora. Díaz’s vivid prose captures the struggles of growing up between two worlds, offering a humorous yet poignant tale of self-discovery. The novel’s unique style and rich cultural insights have made it a landmark in contemporary literature, resonating with readers globally.

Significance of Chapter 1 in the Novel

Chapter 1 of The Brief Wondrous Life of Oscar Wao is pivotal as it introduces Oscar de León, a socially awkward Dominican American teenager, and establishes key themes such as identity, culture, and the curse of fukú. The chapter sets the tone with Yunior’s vibrant narration, blending slang and humor, while delving into Oscar’s struggles with self-acceptance. It portrays his failed relationships and the cultural expectations imposed by his Dominican heritage. This chapter lays the foundation for exploring Oscar’s tragic trajectory, making it essential for understanding the novel’s broader motifs of belonging and destiny. Its rich narrative style captivates readers, drawing them into Oscar’s world.

Author Background: Junot Díaz

Junot Díaz, a Dominican American writer, was born in 1969 in Santo Domingo and raised in New Jersey. His unique voice blends street slang, sci-fi references, and Caribbean culture. Díaz’s work often explores themes of identity, immigration, and cultural displacement. The Brief Wondrous Life of Oscar Wao earned him the Pulitzer Prize in 2008, solidifying his reputation as a major literary figure. His writing style, both raw and lyrical, resonates with readers from diverse backgrounds, making him a celebrated contemporary author.

Plot Summary of Chapter 1

Chapter 1 introduces Oscar de León, an overweight Dominican American teen struggling with identity and unpopularity in high school. The curse of fukú looms over his family.

Oscar de León is portrayed as an overweight, socially awkward Dominican American teenager living in New Jersey. His struggles with identity and cultural expectations are central to the narrative. Unlike the traditional Dominican ideals of masculinity, Oscar is more interested in science fiction and fantasy, making him an outsider among his peers. His physical appearance and lack of social skills contribute to his isolation, highlighting the theme of not fitting into predefined cultural roles. The narrator, Yunior, paints Oscar as a tragic yet endearing figure, whose story intertwines personal and familial history with the supernatural curse of fukú.

The Curse of Fukú

The curse of fukú is a central theme introduced in Chapter 1, portraying it as an ancient, inescapable force of misfortune rooted in African and Caribbean folklore. The narrator describes fukú as a supernatural power that haunts the de León family, contributing to their repeated struggles and tragedies. This concept reflects the tension between fate and personal responsibility, as the characters grapple with their destinies. The curse is depicted as both a cultural superstition and a metaphor for the cyclical nature of suffering, deeply intertwined with the family’s history and identity. Its presence sets the tone for the tragic events that unfold in Oscar’s life.

Oscar’s Struggles in High School

Oscar faces significant challenges in high school, marked by social isolation and a lack of cultural connection. As a Dominican American, he struggles to fit into traditional Dominican masculine ideals, feeling alienated from his peers. His weight and appearance further exacerbate his difficulties, making him a target for ridicule. Academically, Oscar finds solace in science fiction and fantasy, but his intellectual pursuits do not translate to social success. His romantic endeavors, including relationships with Maritza and Olga, end in heartbreak, contributing to his emotional turmoil. These struggles highlight his identity crisis and set the stage for his broader life challenges.

The Role of Family History

fukú, which haunts the de León family, is deeply rooted in their ancestral past, influencing Oscar’s present. Through the narrator’s recounting of his family’s history, readers understand how generational trauma and cultural expectations weigh heavily on Oscar. His struggles in high school are not just personal but also a reflection of his family’s legacy, marked by both resilience and suffering. This intergenerational narrative highlights the enduring impact of the past on Oscar’s journey, connecting his personal story to the broader cultural and historical context of his Dominican heritage.

Themes in Chapter 1

Chapter 1 explores themes of identity, cultural expectations, and the curse of fukú, shaping Oscar’s struggles and his family’s history, deeply influencing his destiny.

The Theme of Identity

Oscar’s identity crisis stems from his dual heritage as a Dominican American. Caught between cultural expectations and personal aspirations, he struggles to reconcile his love for science fiction with traditional Dominican masculinity. His physical appearance and social awkwardness amplify his feelings of alienation, making it difficult for him to fit into either world. This internal conflict is exacerbated by the pressures of family history and the curse of fukú, which further complicates his journey of self-discovery. Through Oscar’s experiences, Díaz highlights the challenges of navigating multiple identities in a society that often demands conformity.

Cultural Expectations and Dominican Heritage

Cultural expectations deeply shape Oscar’s identity, as traditional Dominican ideals of masculinity clash with his reality. The novel highlights how societal norms, such as being a “player” or excelling in sports, are ingrained in Dominican culture. Oscar’s failure to meet these standards, due to his weight and lack of athleticism, isolates him further. His love for science fiction and fantasy, deemed unconventional, adds to his alienation. The curse of fukú symbolizes the historical and cultural burdens passed down through generations, linking Oscar’s struggles to broader themes of identity and belonging. This tension between heritage and self defines much of his journey.

The Concept of Curse and Destiny

The novel introduces the curse of fukú, an ancient and inescapable force believed to plague Oscar’s family. Originating in Africa, this curse symbolizes the inevitability of suffering and misfortune. Oscar’s life is marked by a series of tragic events, from unrequited love to personal failures, which the narrator attributes to fukú. The curse serves as a metaphor for the cyclical nature of destiny, rooted in the family’s history and cultural heritage. It shapes Oscar’s identity and underscores the idea that his fate is predetermined, leaving him powerless against the forces that define his life and ultimately lead to his downfall.

Literary Devices in Chapter 1

Díaz employs a vibrant narrative style, blending slang, Spanglish, and sci-fi references. Magical realism infuses the storytelling, while the narrator’s voice adds a colloquial, intimate tone, enriching the emotional depth.

Narrative Structure and Style

Chapter 1 of The Brief Wondrous Life of Oscar Wao features a non-linear narrative, blending past and present through multiple timelines. The narrator, Yunior, delivers a conversational tone, mixing slang, Spanglish, and sci-fi references, creating a vibrant, dynamic voice. Díaz employs footnotes to delve into historical and cultural contexts, adding layers of depth. The narrative jumps between Oscar’s struggles in high school and glimpses of his family’s past, weaving a complex tapestry of identity and heritage. This unconventional structure mirrors the chaos of Oscar’s life, while the narrator’s informal style fosters intimacy, making the story both deeply personal and universally relatable.

The Use of Magical Realism

Díaz infuses Chapter 1 with magical realism, blending the mundane with the supernatural. The curse of fukú looms as a mystical force shaping Oscar’s destiny. Elements like the family’s haunted past and Oscar’s extraordinary imagination blur the lines between reality and myth. This technique allows Díaz to explore themes of identity and heritage through a lens of enchantment, making the ordinary struggles of Oscar’s life extraordinary. Magical realism enriches the narrative, adding depth and cultural resonance, while grounding the story in a world where the surreal and the familiar coexist seamlessly, reflecting the duality of Oscar’s Dominican American experience.

The Role of the Narrator (Yunior)

Yunior’s voice in Chapter 1 serves as both guide and commentator, offering intimate yet detached insights into Oscar’s life. His narrative style, filled with slang and cultural references, creates a vibrant, authentic tone. Yunior’s perspective balances humor and pathos, humanizing Oscar’s struggles while critiquing Dominican masculinity. His role bridges past and present, weaving family history into Oscar’s story. Yunior’s unreliable narration adds complexity, blending fact and myth, making him a pivotal character in understanding Oscar’s journey. His presence shapes the reader’s perception, blending personal bias with objective storytelling to create a rich, layered narrative that explores identity and cultural heritage.

Character Analysis

Oscar is portrayed as an outcast, struggling with identity and cultural expectations, embodying the curse of Fukú, which shapes his tragic yet unique journey through life.

Oscar’s Character Development

Oscar’s character in Chapter 1 is defined by his struggles with identity, cultural expectations, and self-acceptance. As an overweight Dominican American teenager, he faces ridicule and alienation, unable to align with traditional Dominican masculinity. His love for science fiction and fantasy sets him apart, while his unrequited crushes and social awkwardness deepen his sense of isolation. The narrator, Yunior, paints Oscar as a tragic figure, shaped by the curse of Fukú, which perpetuates his misfortunes. Despite his quirks, Oscar’s sincerity and vulnerability evoke empathy, making him a relatable and sympathetic protagonist in the early stages of the novel.

The Influence of Family Members

Oscar’s family members significantly shape his identity and struggles in Chapter 1. His mother, Belicia, a survivor of poverty and hardship, embodies resilience but also enforces traditional Dominican expectations. Her high standards and disapproval of Oscar’s unconventional interests exacerbate his feelings of inadequacy. Meanwhile, his sister, Lola, serves as both a confidante and a source of friction, reflecting the complexities of sibling relationships. The absence of a strong paternal figure further isolates Oscar, leaving him grappling with cultural and familial pressures. These dynamics highlight how family influences Oscar’s search for belonging and his internalized battles with identity and self-worth.

The Role of Female Characters in Oscar’s Life

Female characters in Oscar’s life play pivotal roles in shaping his emotional and psychological landscape. Maritza, his elementary school girlfriend, represents unattainable love and early heartbreak. Her rejection leaves Oscar with deep insecurities, influencing his future relationships. Olga, another girlfriend, symbolizes Oscar’s struggles with self-worth, as he feels guilty for hurting her. These interactions highlight Oscar’s internalized inadequacy and his inability to reconcile his desires with societal expectations. The women in his life serve as mirrors, reflecting his insecurities and reinforcing the curse of fukú, which haunts his family. Their presence underscores themes of love, loss, and identity central to the narrative.

Cultural and Historical Context

The novel blends Dominican culture with American life, exploring themes of immigration and identity. Historical references, such as the curse of fukú, ground Oscar’s story in ancestral heritage.

Dominican Culture and Traditions

Dominican culture is deeply intertwined with Oscar’s identity, as seen in his family’s traditions and values. The novel highlights the vibrant music, food, and folklore that shape his heritage. Chapter 1 introduces the concept of fukú, a curse rooted in Afro-Dominican beliefs, reflecting the blending of African, indigenous, and Spanish influences. These cultural elements contrast with Oscar’s struggles to fit into both Dominican and American worlds, showcasing the tension between preserving heritage and adapting to a new environment. The Chapter also touches on the importance of family, respect, and masculinity in Dominican culture, which profoundly impacts Oscar’s self-perception and behavior.

Immigration and Identity Crisis

Oscar’s struggles in Chapter 1 reflect the broader tensions of immigration and identity faced by Dominican Americans. His family’s migration from the Dominican Republic to the United States creates a cultural divide, leaving Oscar caught between two worlds. The chapter portrays his alienation as he fails to meet traditional Dominican expectations of masculinity and success, while also feeling disconnected from American culture. This duality exacerbates his sense of isolation, making it difficult for him to forge a cohesive identity. The narrative underscores the challenges of navigating multiple cultural identities, a common experience for children of immigrants. This internal conflict shapes Oscar’s worldview and interactions.

Historical References in the Chapter

Chapter 1 of The Brief Wondrous Life of Oscar Wao incorporates historical references that highlight the migrant experience and cultural identity. The narrative touches on the Dominican Republic’s complex past, including the oppressive regime of Rafael Trujillo, which indirectly shapes the lives of Oscar’s family. These historical allusions provide context for the cultural expectations and traditions that influence Oscar’s struggles. The chapter also subtly reflects the broader history of immigration, particularly the challenges faced by Dominican Americans navigating two worlds. These references enrich the story, connecting Oscar’s personal journey to a larger historical and cultural framework.

Symbolism and Motifs

The curse of fukú symbolizes inherited misfortune, shaping Oscar’s destiny. Weight and appearance mirror internal struggles, while names reflect identity and heritage, grounding the story in cultural and familial history.

The Significance of Names and Naming

In The Brief Wondrous Life of Oscar Wao, names carry deep cultural and familial significance. Oscar, named after a literary figure, embodies intellectual aspirations, while Yunior reflects generational ties. Names like Belicia and Lola connect characters to their Dominican heritage, symbolizing identity and continuity. The narrator often uses nicknames, such as “Oscar Wao,” blending Spanish and English, highlighting cultural blending. Naming also underscores themes of belonging and displacement, as characters navigate dual identities. The weight of names mirrors the burdens of family history and expectations, making them a powerful motif in exploring identity and cultural legacy.

The Symbolism of Weight and Appearance

Oscar’s weight and appearance symbolize his internal struggles and societal alienation. His obesity reflects the burden of unmet expectations and cultural pressures. In a Dominican culture that values traditional masculinity, Oscar’s physique marks him as an outsider. His weight gain after Maritza’s rejection symbolizes emotional turmoil and loss of control. Appearance also serves as a metaphor for identity; Oscar’s mismatch between his inner self and external image highlights his fractured sense of self. This contrast underscores themes of belonging and self-acceptance, as Oscar grapples with both personal and cultural perceptions of beauty and worth.

The Role of Love and Heartbreak

Love and heartbreak are central to Oscar’s identity and struggles. His unrequited loves, particularly with Maritza and Ana Obregón, symbolize his longing for connection and acceptance. Maritza’s rejection leaves Oscar emotionally shattered, marking a downturn in his life. Heartbreak reflects his inability to conform to Dominican ideals of masculinity and romance. Love becomes both a source of hope and pain, highlighting Oscar’s vulnerability. These experiences shape his perception of himself and the world, underscoring themes of isolation and the search for belonging. Heartbreak, in particular, amplifies his sense of helplessness and strengthens the narrative of his tragic destiny.

Reception and Analysis

The Brief Wondrous Life of Oscar Wao received widespread acclaim for its original storytelling and cultural depth. Critics praised its blend of humor and heartbreak, while scholars highlighted its exploration of identity and Dominican heritage, solidifying its status as a modern literary masterpiece.

Critical Reception of Chapter 1

Chapter 1 of The Brief Wondrous Life of Oscar Wao has been praised for its bold narrative voice and vivid portrayal of Oscar’s struggles. Critics highlight its originality in blending humor with poignant cultural insights, setting the tone for the novel’s exploration of identity and heritage. The chapter’s focus on Oscar’s adolescence resonates deeply, offering a relatable yet unique perspective on growing up Dominican in America. Scholars emphasize its rich thematic layers, particularly the interplay of personal and cultural identity, making it a foundational part of the novel’s acclaim. Its impact on contemporary literature is undeniable, solidifying Díaz’s storytelling genius.

Reader Responses and Interpretations

Readers have deeply connected with Oscar’s struggles in Chapter 1, empathizing with his outsider status and cultural conflicts. Many interpret his story as a universal tale of self-discovery, resonating with themes of identity and belonging. The chapter’s vivid portrayal of Oscar’s adolescence evokes nostalgia and reflection, particularly among those familiar with immigrant experiences; Fans praise its raw honesty and emotional depth, while others highlight its relatability in exploring societal expectations versus personal desires. The narrative’s blend of humor and pathos creates a strong emotional bond, making Oscar’s journey feel both deeply personal and broadly human. This connection fosters a lasting impact on readers.

Academic Analysis of Key Themes

Scholars highlight the profound exploration of identity, culture, and destiny in Chapter 1 of The Brief Wondrous Life of Oscar Wao. The academic community emphasizes how Díaz uses Oscar’s struggles to illustrate the tensions between Dominican heritage and American assimilation. The concept of fukú is analyzed as a metaphor for inherited trauma and cultural legacy; Researchers also explore how Oscar’s outsider status reflects broader immigrant experiences, blending personal and collective histories. The chapter’s narrative style and themes are praised for their depth, offering insights into the complexities of identity formation and the interplay of tradition and modernity.